+86 18292768861

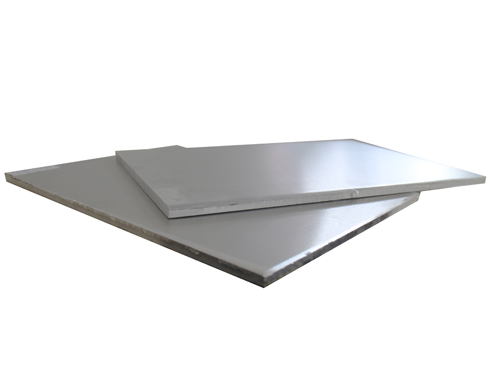

High purity aluminum plate

The common codes of pure aluminum plate series are 1050, 1060 and 1100. In all aluminum plate series, pure aluminum plate series belongs to the series with the most aluminum content.

The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively single and the price is relatively cheap. It is the most commonly used series in conventional industry at present. At present, most of the products in circulation in the market are 1050 and 1060 series.

Excellent characteristics of pure aluminum:

1. Low density: the density of pure aluminum is close to 2700kg / m3, about 35% of that of iron.

2. Hardenable: the strength of pure aluminum can be more than doubled by cold working. Moreover, it can be alloyed by adding magnesium, zinc, copper, manganese, silicon, lithium, scandium and other elements, and then further strengthened by heat treatment. Its specific strength can be comparable to that of high-quality alloy steel.

3. Easy processing: aluminum is cast by any casting method. Aluminum has good plasticity and can be rolled into sheet and foil; Drawing into pipes and filaments; Extruded into various civil profiles; It can carry out turning, milling, boring, planing and other machining at the maximum speed that most machine tools can achieve.

4. Corrosion resistance: on the surface of aluminum and its alloys, it is easy to form a dense and firm Al2O3 protective film. This protective film will be damaged only under the intense action of halogen ions or alkali ions. Therefore, aluminum has good resistance to atmospheric (including industrial atmosphere and marine steam) corrosion and water corrosion. It can resist the corrosion of most acids and organic substances. It adopts corrosion inhibitor and can resist the corrosion of weak alkali solution; The corrosion resistance of aluminum alloy can be improved by adopting protective measures.

5. No low temperature brittleness: aluminum is below zero degrees Celsius. With the decrease of temperature, the unfairness of strength and plasticity will not decrease, but increase.

6. Good conductivity and thermal conductivity: the conductivity and thermal conductivity of aluminum are just inferior to that of silver, copper and gold.

7. Strong reflectivity: the reflectivity of aluminum polished surface to white light is more than 80%. The higher the purity, the higher the reflectivity. At the same time, aluminum has good reflection properties to infrared, ultraviolet, electromagnetic wave and thermal radiation.

8. No magnetism, impact, no spark. 9. Sound absorption. 10. Resistance to nuclear radiation. 11. Beautiful.

Comparison of pure aluminum plates:

1. Brand: 1a85, 1a90, 1a93, 1a97, 1a99;

Product type: plate, strip, foil, pipe;

Main features: industrial high purity aluminum;

Scope of application: it is mainly used to produce various foil materials and acid resistant containers for electrolytic capacitors. The products include plates, tapes, foils, etc.

2. Brand: 1060, 1050A, 1035;

Product type: foil, wire;

Main features: industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity, but it has low strength, can not be strengthened by heat treatment, and has poor machinability. Contact welding and gas welding are acceptable;

Scope of application: make use of its advantages to manufacture some structural parts with specific performance, such as gaskets and capacitors made of aluminum foil, electronic tube isolation network, protective sleeves, nets, wire cores of wires and cables, aircraft ventilation system parts and decorative parts.

3. Brand: 1100;

Product type: plate and strip;

Main features: it is ordinary industrial pure aluminum with aluminum content of 99.0%, which can not be strengthened by heat treatment; Low strength, but good ductility, formability, weldability and corrosion resistance; After anodizing, the corrosion resistance can be further improved and a beautiful surface can be obtained at the same time;

Scope of application: mainly produce plate and strip. It is suitable for making all kinds of deep stamping products and is widely used in various fields from cookware to industrial equipment.

Surface quality requirements of pure aluminum plate

1. The surface of the plate shall be clean and free of cracks and oxidized sundries.

2. The plate surface is allowed to have defects such as indentation, scratch and roll indentation, but its depth shall not exceed the allowable negative deviation of the plate, and the minimum thickness shall be guaranteed.

3. The process aluminum clad thick plate is allowed to have the falling off part of the coating and the bubbles of the coating.

4. Defects within the thickness difference range are allowed to be repaired on the plate surface.

5. Other requirements: formulated by the demander and supplier.

Hotline

+86 18292768861