+86 18292768861

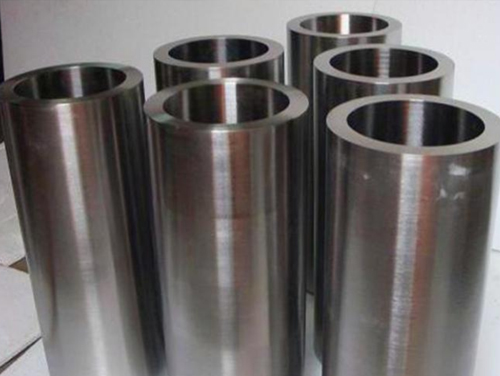

Titanium tube has the advantages of light weight, high strength and superior mechanical properties. It is widely used in heat exchange equipment, such as tubular heat exchanger, coil heat exchanger, coil heat exchanger, condenser, evaporator and transmission pipeline. Many nuclear power industries take titanium tubes as the standard tubes for their units.

Titanium pipe shall comply with two national standards: GB / t3624-2010 GB / t3625-2007 ASTM b337 338 according to different use requirements and properties

Supply brand: TA0, TA1, TA2, ta9, TA10, bt1-00, bt1-0, GR1, Gr2

Production standard

I. referenced standards

1. GB 228 metal tensile test method

2. GB 224 metal pipe hydraulic test method

3. GB 226 metal tube flattening test method

4. GB / t3620.1 grades and chemical composition of titanium and titanium alloys

5. GB / t3620.2 chemical composition and allowable deviation of titanium and titanium alloy processing products

II. Technical requirements

1. The chemical composition of titanium and titanium alloy pipes shall comply with the provisions of GB / t3620.1. During the re inspection by the demander, the allowable deviation of chemical composition of Mingkun titanium industry shall comply with the provisions of GB / t3620.2.

2. The allowable deviation of pipe outer diameter shall comply with the provisions in table I.

3. The allowable deviation of pipe wall thickness shall not exceed ± 12.5% of its nominal wall thickness. The allowable deviation of pipe wall thickness is not applicable to the weld of titanium welded pipe.

4. The length of pipes shall comply with the provisions in Table 2.

5. The fixed length or double length of the pipe shall be within its variable length range, and the allowable deviation of the fixed length shall be + 10mm. The double length shall also be included in the cut amount when the pipe is cut, and each cut amount shall be 5mm.

Hotline

+86 18292768861