+86 18292768861

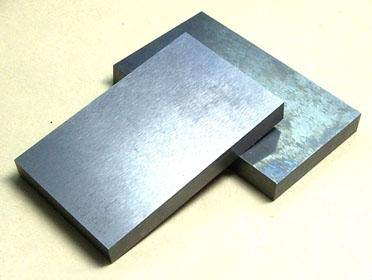

Molybdenum plate

Molybdenum is hard and soft. It is more tough than tungsten. Molybdenum has high elastic modulus, while tungsten and tantalum only have high melting point. Molybdenum plate is used in many special steels. Other common uses are molybdenum electrodes, vacuum furnace applications, nuclear power, missile and aircraft parts.

The thickness ranges from 00.090 inches to 3 inches and is listed as molybdenum plate. Molybdenum plate is widely used in mold and parts furnace construction, electronic and semiconductor industry parts manufacturing.

Organosilicon molybdenum plate is made of silicon source si2cl6 and silicification conditions and some of its properties are reviewed. The molybdenum silicide in this plate is deposited first, such as 4 MoSi2. In the initial stage, it is 6 meters thick (after 10 minutes), and then it is combined and stored. After 30 minutes, a uniform MoSi2 silicide plate is formed. The weight of the organic silicon plate dissolved by anode is doubled in 0.2 M sulfuric acid, which reduces the thickness of MoSi2 layer. The corrosion of sea water and sea sand and the wear of silicon molybdenum plate increase the resistivity, thus increasing the silicification temperature and the flow rate of si2cl6.

Appearance of molybdenum plate: silver gray metallic luster.

Specification (mm): BCM = 9.9 (0.3-10) (60-400) above 800

Content: molybdenum content 99.95% ~ 99.6%, impurity content ≤ 0.04%

Density: the density of molybdenum in molybdenum plate is 10.2g/cm3

Performance: corrosion resistance

Process: extrusion, forging, rolling

Purpose: mold and parts furnace construction, electronic and semiconductor industry components manufacturing

Hotline

+86 18292768861