+86 18292768861

Tungsten rod is also called tungsten alloy rod. Tungsten alloy rod (wmonife) and anviloy 1150 are made of metal powder at a specific high temperature, using a special high temperature powder metallurgy technology. In this way, the thermal expansion coefficient of tungsten alloy rod material is low and the thermal conductivity is good.

And good material properties.

At high temperature, tungsten alloy rod is a material with high melting point and low coefficient of thermal expansion. The addition of tungsten alloy improves machinability, toughness and welding. Material properties are built on manufacturing tungsten alloy rods to eliminate heat treatment related problems with other tool materials.

Tungsten rod has special properties, such as low thermal expansion and good thermal conductivity, enough resistance and high elastic modulus. Therefore, tungsten rods are widely used in various fields. Such as support line, lead-in line, printer needle, various electrodes and quartz furnace, filament, high-speed tools, auto products, sputtering target.

Material and batch number: W1, wAL1, wal2

Application fields: glass melting; high temperature furnace heater, structural parts; welding electrode; filament; weapons for X-37B

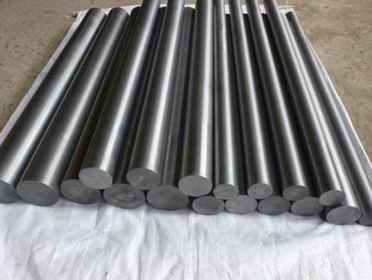

Supply form: rotary forging, turning and polishing.

Processing methods: sintering, forging, rotary forging, rolling and polishing.

Color classification of tungsten rod surface:

1. The surface of sintered tungsten rod is silver gray metallic luster;

2. There is a layer of oxide on the surface of forged tungsten rod, and the surface is black;

3. Polished tungsten rod, silver gray metallic luster.

Hotline

+86 18292768861